Technology

-

Metallized films

Use of metallized films has virtually taken over most capacitor applications in the past few decades. The advantages offered by metallized films have proved to be of immense value in major areas by way of…

-

POLYPROPYLENE AND POLYESTER FILM

Plastic film capacitors are mostly used in high-performance applications. Polycarbonate, polyester and polypropylene have been the ‘big three’ of film capacitors. Most capacitor manufacturers have been using these all along, although use of polyethylene naphthalate…

-

Properties of dielectrics

Dielectrics are materials that define most of the parameters of capacitors, such as capacitance, loss factor, voltage capacities etc. All dielectrics are insulators. An insulator used between plates or electrodes of capacitor as a supporter…

-

Introduction to Capacitors

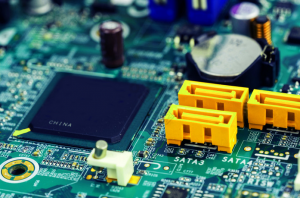

The capacitor is one of the three basic passive circuit components of any electronic or electrical circuit. Resistance in a circuit gives rise to oh-mic or watt losses, and its current is in phase with…

-

Variable Capacitor

A variable capacitor allows adjustment of capacitance in much the same way that a potentiometer allows adjustment of resistance. Large variable capacitors were developed primarily to tune radio receivers, in which they were known as…

-

Capacitor: The core energy storage component of modern electronic devices

A capacitor connected across a DC power source will accumulate a charge, which then persists after the source is disconnected. In this way, the capacitor stores(and can then discharge)energy like a small rechargeable battery. The…

-

Discover the benefits of aluminum electrolytic capacitors

Aluminium electrolytics do not have competition from tantalum or other capacitors in highervoltages as other electrolytics are essentially for low voltage applications. Even in low voltage,they have the advantage of lower cost per unit. There…

-

An introduction to the manufacturing process of aluminum electrolytic capacitors

The manufacturing process of aluminum electrolytic capacitors is mainly for the slitting, nailing, impregnation, assembly, casing, aging, testing of positive foil, negative foil, electrolytic capacitor paper, etc.

-

Electrolytic capacitor paper and electrolyte

The electrolyte as the negative electrode needs to be loaded, and at the same time, it is also necessary to add a physical barrier between the positive and negative foil to prevent the collision between…

-

Acquisition of cathode foil and dielectric film: formation

The positive electrode of the aluminum electrolytic capacitor is made into an uneven corrosive foil, and the dielectric film also needs to be in close contact with the uneven positive or negative foil, and there…