The positive electrode of the aluminum electrolytic capacitor is made into an uneven corrosive foil, and the dielectric film also needs to be in close contact with the uneven positive or negative foil, and there can be no air or other dielectric parts with low dielectric constant in the middle. This dielectric film is the alumina film.

One of the most commonly used metals in everyday life is aluminum. In order to increase the surface hardness and wear resistance of aluminum, it is usually necessary to carry out cathodic oxidation on the surface of aluminum, and increase the surface hardness by increasing the thickness of the alumina film.

Alumina is a good insulator, and the relative dielectric constant is very high (about 8), and the dielectric strength is also very high (about 800*106V), so it is a good dielectric material.

Fortunately, aluminium is a “valve metal” that can be anodicized to form an alumina dielectric layer on the surface of aluminum, which depends on the voltage applied during cathode oxidation.

In addition to aluminum, metals that can form an oxide film medium on the metal surface by cathodic oxidation are tantalum, niobium, titanium, etc., which are collectively referred to as valve metals. The aluminum or tantalum anodizing method is used to form a dense oxide film on the surface of aluminum or buttons, which is used as the insulating medium of electrolytic capacitors.

The relative dielectric constant of alumina and tantalum oxide is large (the relative dielectric constant of alumina is 8 and tantalum oxide is about 20, which is much higher than the 2~3 of general films).

In order to effectively utilize the relative permittivity of alumina and tantalum oxide, the electrode of the electrolytic capacitor must be in close contact with the alumina or tantalum oxide and the uneven insulating medium, and there shall be no other medium with low relative dielectric coefficient such as air in the middle of the two.

And the manganese nitrate liquid needs to be immersed in the tantalum block, and the manganese nitrate decomposes to produce manganese dioxide, which forms the actual negative electrode of the button electrolytic capacitor and forms close contact with the tantalum oxide medium.

In addition to aluminum, which has good ductility, the other valve metals are relatively hard and far less malleable than aluminum, so the rest of the valve metals are used to form electrolytic capacitors, and the valve metal is usually pressed into a porous metal block similar to foam in the form of particles and sintered to increase the surface area.

Alumina films with uniform thickness and texture can be obtained in the form of cathode oxidation, and the thickness of the alumina film can be precisely controlled by controlling the cathode oxidation voltage. Even with a rough surface, the thickness and texture uniformity of the alumina film are not affected, and it is in close contact with aluminum. This lays the most solid first step for the realization of aluminum electrolytic capacitors.

The process of “cathode oxidation” is as follows: the positive foil on the aluminum foil coil is passed through the electrolyte tank, and the DC voltage between the tank and the foil is continuously applied to complete the alumina film formation process. The voltage is 135%~200% of the rated voltage of the final capacitor, therefore, the dielectric thickness of the aluminum electrolytic capacitor can be precisely controlled.

Generally, the correspondence between the thickness of alumina and the voltage is IV corresponding to 1.2~1.5nm, such as the positive foil formation voltage of 450V capacitors can be greater than 600V, and the thickness of alumina is 720~900nm, less than 1/100 of the diameter of a human hair.

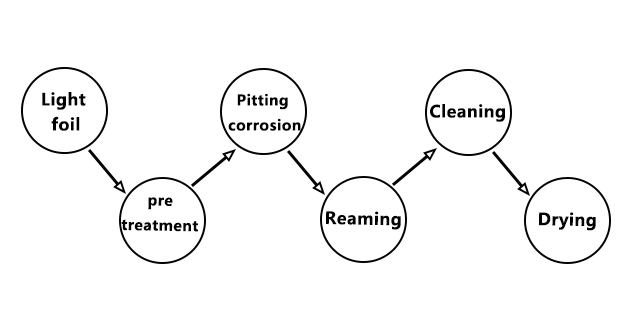

Since the particularly fine parts of the corroded foil may be blocked by alumina, cathode oxidation reduces the effective area of the cathode foil surface. The high-pressure cathode corrosion foil has one more reaming process than the low-pressure cathode foil or the negative electrode foil.

High-pressure cathode foil corrosion process

Due to the brittleness of alumina itself, the “too thick” alumina film will be brittle when the electrolytic capacitor is wound, making the aluminum electrolytic capacitor’s

Performance decreases, which is why it is rare to see aluminum electrolytic capacitors with a rated voltage above 600V.