Precautions when using

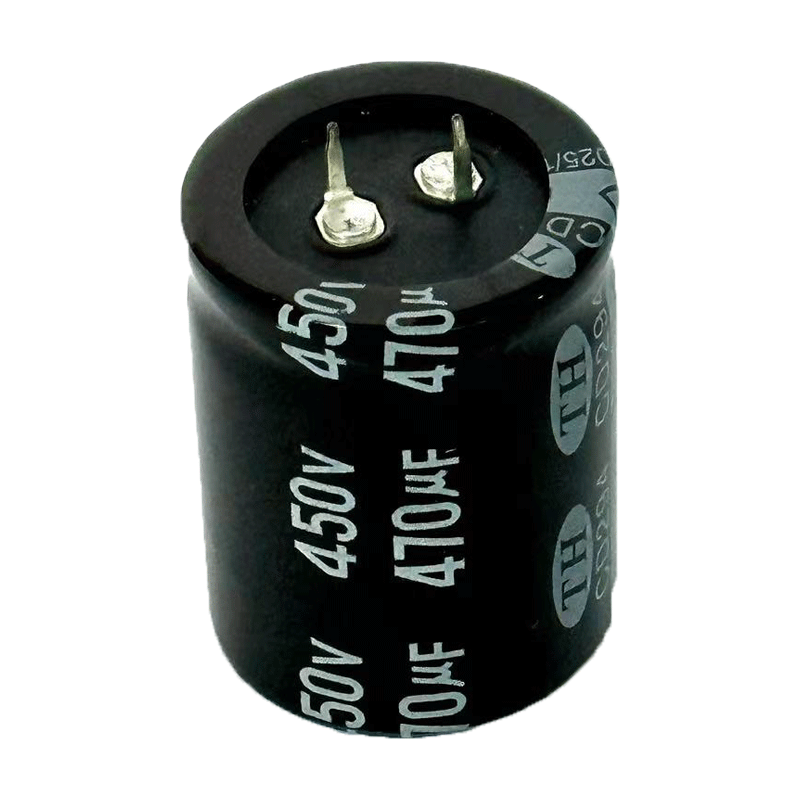

1.Ordinary aluminum electrolytic capacitors are polarized.

When using, check the polarity mark, the short lead is the negative pole, and the long lead is the positive pole. In addition, there is also a negative symbol on the sleeve of the product.

If the voltage is applied in the opposite direction, the circuit will be short-circuited and the capacitor will be damaged. In circuits with unknown or uncertain polarity, use bipolar aluminum electrolytic capacitors.

2. Please use at or below the rated voltage.

Once the applied voltage exceeds the rated operating voltage, the leakage current will increase sharply, and heat will cause the product to open the valve or break down and fail.

3. Ordinary aluminum electrolytic capacitors are not suitable for frequent charging and discharging.

If the capacitor is heated up due to frequent charging and discharging in the circuit, the leakage current increases, and the capacitance decreases, which will also damage the capacitor. If you want to use it in such a circuit, you need to design an aluminum electrolytic capacitor that is resistant to charging and discharging.

4. Aluminum electrolytic capacitors are not suitable for use in circuits that exceed the allowable ripple current range.

If the ripple current required to flow through the circuit exceeds the allowable ripple current, use an aluminum electrolytic capacitor with high ripple current.

5. Aluminum electrolytic capacitors should not be used when the ambient temperature exceeds the upper operating temperature specified in the standard.

6. If the aluminum electrolytic capacitor has been stored for a long time, it should be freshly refined before use.

Because the leakage current of aluminum electrolytic capacitors tends to increase after long-term storage, which is caused by the deterioration of the dielectric film in the no-load state.

The voltage is applied to re-age to repair the dielectric oxide film and reduce the leakage current before it can be reused.

7.Aluminum electrolytic capacitors should be stored in a low ambient temperature and dry place.

Aluminum electrolytic capacitor

Installation precautions

1. There is no insulation between the aluminum shell of the aluminum electrolytic capacitor and the cathode lead-out wire, please note!

2. Do not stress the lead wire of the aluminum electrolytic capacitor, otherwise it may cause the lead wire to break and open the circuit due to the collision welding between the aluminum stem, or the short circuit, or the leakage current increases.

3. When the overall size of the aluminum electrolytic capacitor with lead structure is more than ∅18mm, the lead wire is not used for fixing.

4. When installing and welding aluminum electrolytic capacitors, the temperature should not exceed 27°C, and the welding time should be controlled within 4 seconds.

5. The hole spacing of the aluminum electrolytic capacitor inserted into the printed circuit board should match the lead spacing of the capacitor.

If the hole spacing of the printed board is too large or too small, it is easy to cause the leakage of electrolyte, the increase of leakage current, the shortening of life and even the open circuit of aluminum electrolytic capacitors.

6.When inserting a capacitor with a rubber plug anti-drying structure, it is required that the position corresponding to the printed circuit board and the rubber plug explosion-proof hole be opened to facilitate ventilation.