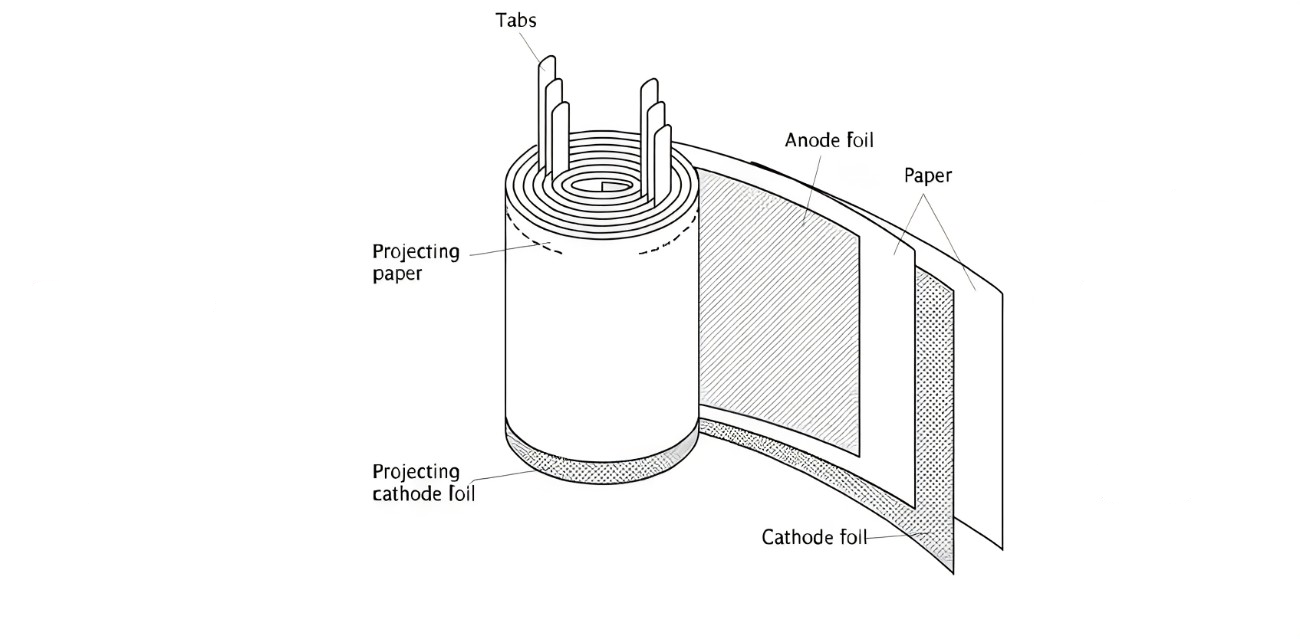

The basic structure of general-purpose aluminum electrolytic capacitors is a foil-wound type. The anode is aluminum metal foil, and the medium is the valve metal oxide film Al2O3 formed on the surface of the anode metal foil by electrochemical methods.

Compared with the structure of other types of capacitors, such as ceramic dielectric capacitors and organic film capacitors, it has the following significant differences:

- The two conductive plates of an electrolytic capacitor are divided into positive and negative electrodes.

- The medium of the electrolytic capacitor is to use electrochemical methods to generate an extremely thin layer of aluminum oxide film of about 0.01~1um on the surface of the corroded anode aluminum foil as the dielectric of the thermal capacitor, which is combined with the aluminum anode as a whole.

- The cathode of an electrolytic capacitor is the electrolyte. Electrolytes can be classified into liquid electrolytes, semi-liquid (paste, gel) electrolytes, and solid electrolytes based on their physical state. In order to connect the cathode of the capacitor with the external circuit, a cathode lead wire must be added to the structure to form a complete structure. The electrolytic paper in the capacitor is used to isolate the electrolyte and the gasket for adsorption.

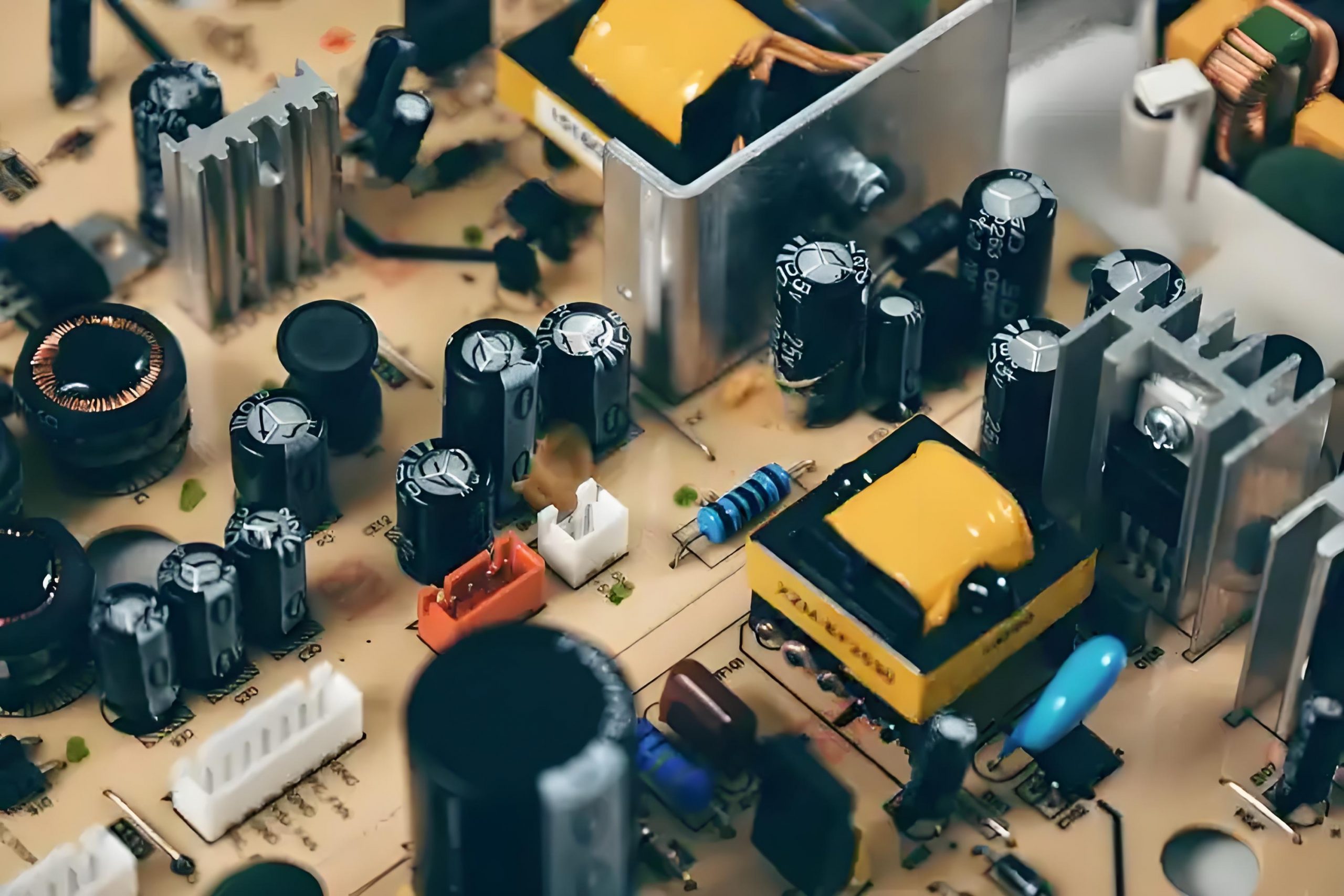

Schematic diagram of the structure of a winding electrolytic capacitor

Due to the characteristics of the electrolytic capacitor’s own structure, this type of capacitor has its own unique advantages in terms of performance, but it also brings some inevitable disadvantages.